Philosophy

A note from our Founder, Sophie Mckay

Our brand represents an ongoing evolution to foster optimistic change in the jewellery

industry, innovating to reduce our environmental impact, as well as harnessing positive

social progress – from our studio and supply chain to our wider local communities. We set ourselves extremely high targets and our journey is one of constant change, in an effort to consistently do better than we did yesterday.

As part of our ever evolving journey, I want to be as honest and open with our customers and supportive community about what that looks like. As we share insights into our thorough and thoughtful approach to what we do, we invite you to ask questions, make suggestions and join the conversation to help us be better.

While we focus on improving in various areas of sustainability and ethical practice, our business aims to address the below 3 specific areas of concern :

Responsible Consumption

We design timeless pieces that are a reaction against fast fashion

-

Responsible Production

Ensuring the people who produce our products are treated fairly

-

Respect for the Environment

Responsible sourcing and correct handling and disposal of chemicals

The materials we use

RECYCLED SILVER

We love to work with silver, it is a material that allows us to create beautiful, minimalistic pieces that can be kept for years to come. We collaborate only with suppliers who share our commitment to sustainability, where certified recycled silver is always used. By reusing what already exists, we can extend the life of the metal but also help to reduce the environmental impact of mining and lower our CO₂ emissions.

The recyclability of silver is fascinating, it is recovered from unexpected everyday objects such as electronics, medical equipment and more obvious sources such as jewellery industry overproduction. It can be transformed into something entirely new without ever losing its beauty, quality, or value.

RESPECT FOR THE ENVIRONMENT

-

Sustainable Focus

Recycling

Correct disposals of chemicals

RESPECT FOR PEOPLE

-

Fair Wages

Fair Working Hours and Rest Periods

Community Centered

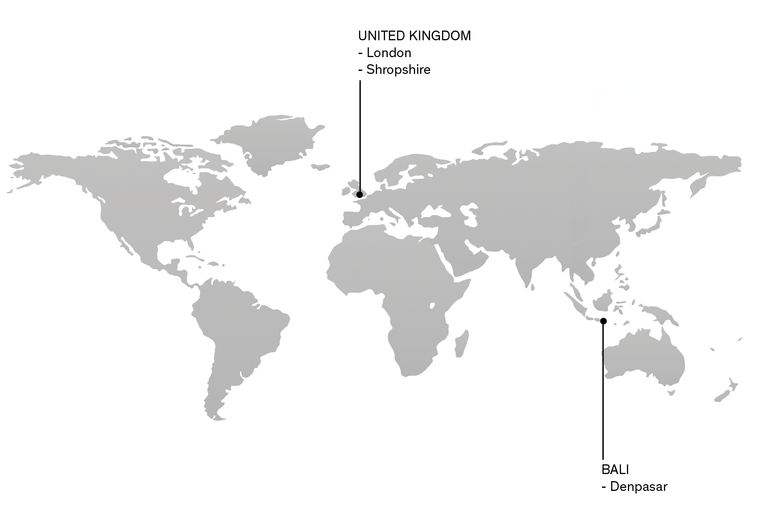

Where we produce

United Kingdom

Our East London Studio

Vegan, Non toxic polishing compounds

Work with local skilled makers

Re-Polishing and Re-Plating service

-

Central London Factory

Recycled Metals

Family Owned

-

Shropshire Factory

A member of the Responsible Jewellery Council

Recycled Metals

Family Owned

Bali

Denpasar Factory

Sustainable approach and innovation

Community Projects

Contribute to local charities

Recycled Metals

-

Fair Wages

Highly skilled artisans

Our Packaging

100% RECYCLED

or

FSC®-CERTIFIED

The FSC® mark guarantees that all materials come from an FSC® forest, where no more wood is cut down than the forest can reproduce. This means better protection of the animal and plant life, and all foresters have proper training, safety equipment and a decent wage.

-

MADE IN DENMARK AND TAIWAN

-

RECYCLABLE AND 100% PLASTIC FREE

Our Ongoing Journey

If you would like to know anything else about our process, please contact us at info@barjewellery.com